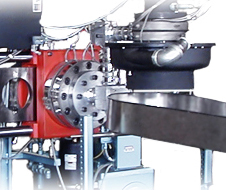

Water Ring Pelletizer

- Output ranges from 20 lbs/hr to 15,000 lbs/hr

- Utilizes hot die face method to cut pellets, then pellets are thrown into a water circulating cooling ring

- Produces consistent sized dry pellets

- Balanced melt flow from upstream equipment to die-cutting surface with no flow interruption

- Able to process PE, PP, LDPE, LLDPE, HDPE, HMWPE - HPDE, ABS, EPS, PS, and many other types of materials

- Easily accomodates a variety of extruder centerline heights

- Unique filtration system produces pellets that are free of fines and overs

- Utilizes an efficient centrifugal dryer to ensure dry pellets

- Self-contained control system allows ease-of-use, and flexibility to move the pelletizer when necessary

- Electrically heated and controlled die face and body

- Specially designed cooling chamber ensures pellet quenching and minimizes agglomeration

- Flexible cutting knives are easily adjusted with a variable speed digital drive

- Pellet length is easily adjusted with a variable speed digital drive

- Long-lasting shaft and bearing components

- Electrical interlocks ensure operator safety

- Compact, space saving design