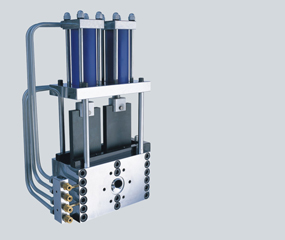

Dual Flat-Plate Hydraulic Screen Changer (polymer filtration)

Function

Features

Benefits

Technical Data

The dual flat-plate hydraulic screen changer is based on the slide-plate screen changer. It provides screen changing without stopping production by alternating between two plates

Dual flat-plate hydraulic screen changers are used in compounding, masterbatch, recycling, sheet extrusion, profile extrusion, pipe production, pipe coating, and biaxial orientation.

Function

- Hydraulic cyclinder moves one plate out of the housing

- Polymer melt flow passes through the other filter screen during changes

- Old screen is replaced with clean one and the plate is returned to the production position

- Polymer melt flows back through the two screen again until another screen change is necessary

Features

- 500 kg/hr - 2,000 kg/hr

- Works well at high pressures of 25MPa - 30MPa

- Polymer melt separated between two plates (one screen in each plate) on the inlet side

- Provides continuous production

- Twice the filtering area makes it suitable for high output extrusion lines

- Uses a a precise electrical ruler controller system

- Hydraulic system provides secure operation

Benefits

- Screen changing is less than 2 seconds

- No air bubbles in product

- Higher output rate than slide-plate screen changer because twice the filtering area

- Compact design shortens the heating period and reduces heat loss

- Good for thermally sensitive materials

- Unique sealing systems ensures operation without leaks

Technical Data

| Model | Screen Area (cm²) | kg/hr | lbs/hr |

|---|---|---|---|

| CDP-70 | 26 | 100 - 350 | 220 - 770 |

| CDP-100 | 60 | 150 - 400 | 330 - 880 |

| CDP-120 | 72 | 200 - 600 | 440 - 1,325 |

| CDP-150 | 134 | 200 - 600 | 440 - 1,325 |