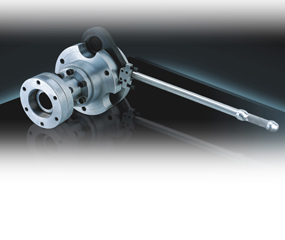

Manual Screen Changer (polymer filtration)

Function

Features

Benefits

Technical Data

Manual screen changers are used in compounding, masterbatch, recycling, sheet extrusion, profile extrusion, pipe production, pipe coating, and biaxial orientation.

Function

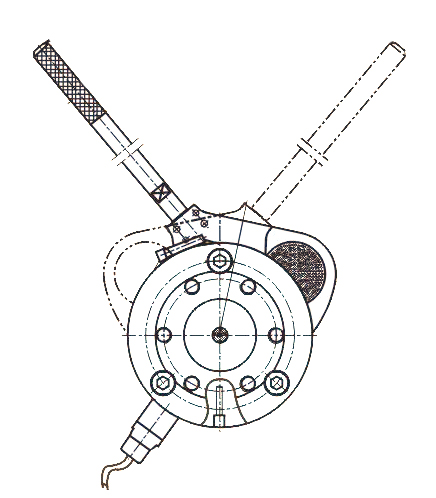

- Production must be stopped prior to filter screen change

- Manually move clean filter screen into the melt flow position

- Production can be restarted after clean filter screen is moved into position

- Used filter screen then is cleaned and ready for use again when second filter screen requires changing

Features

- Suitable for low output extruders under 90 kg/hr

- One breaker plate in polymer melt flow during production

- Second filter plate has clean screen outside of the polymer melt flow

Benefits

- Protects gear pumps and fine extrusion die gaps from damage and dirt accumulation

- Good for low output extruders

Technical Data

| Model | Screen Area (cm²) | kg/hr | lbs/hr |

|---|---|---|---|

| CM-50 | 8 | 50 | 110 |

| CM-55 | 11 | 75 | 165 |

| CM-65 | 13 | 80 | 175 |

| CM-70 | 16 | 90 | 200 |

| CM-100 | 35 | 130 | 285 |