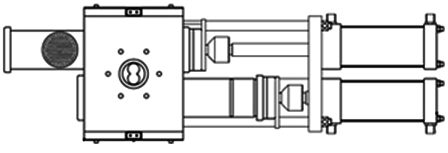

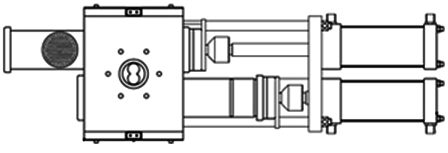

Dual Bolt Hydraulic Screen Changer (polymer filtration)

Function

Features

Benefits

Technical Data

The dual bolt hydraulic screen changer allows for the changing of polymer filtration screens without stopping production by alternating bewtween to bolt positions.

All gas in the polymer melt can be discharged through an advanced gas exhaust system design. This provides continuity and stability of the production process.

Dual bolt hydraulic screen changers are used in compounding, masterbatch, recycling, sheet extrusion, profile extrusion, pipe production, pipe coating, and biaxial orientation.

Function

- Hydraulic cyclinder moves one bolt (piston) out of the housing

- All polymer melt flows other filter screen during change

- Old screen replaced with clean one bolt (piston) is returned to production position

- Polymer melt flows back through the two screens again until another screen change is necessary

Features

- Melt is separated between two bolts (pistons), each bolt uses one filter screen on the inlet side

- Filter screens capture all contaminates while polymer melt flows through the filter screens

- Uses advanced gas discharging system

- Dual filtering areas make it suitable for high output extrusion lines

Benefits

- Simultaneuous screen changing and gas discharging provides continuous production

- No air bubbles in production output

- Screen changing is less than 2 seconds

- Higher output rate than single bolt screen changer because of dual filtering area

- Unique sealing system ensures operation without leaks

- Short residence time for materials

Technical Data

| Model | Screen Area (cm²) | kg/hr | lbs/hr |

|---|---|---|---|

| CDB-70 | 26 | 100 - 300 | 220 - 660 |

| CDB-100 | 60 | 150 - 400 | 330 - 880 |

| CDB-120 | 72 | 200 - 600 | 440 - 1,325 |

| CDB-150 | 134 | 300 - 800 | 660 - 1,765 |