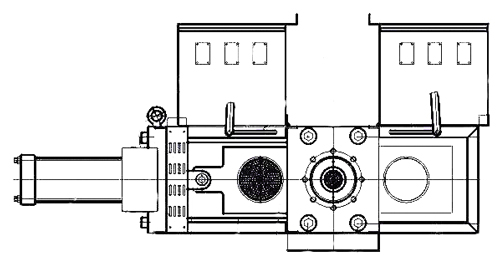

Slide-Plate Hydraulic Screen Changer (polymer filtration)

Function

Features

Benefits

Technical Data

The slide-plate hydraulic screen changer is designed to work with extruders of different specifications and is capable of processing most polymers at high outputs.

Slide plate hydraulic screen changers are used in compounding, masterbatch, recycling, sheet extrusion, profile extrusion, pipe production, pipe coating, and biaxial orientation.

Function

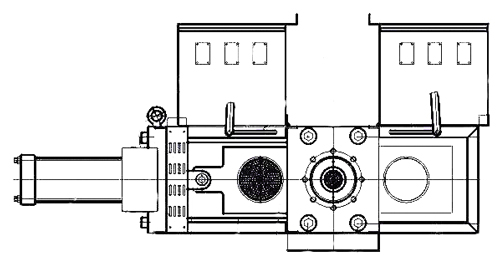

- Hydraulic cyclinder slides the plate out of the housing and polymer melt begins to flow through the second screen

- After replacing the filter screen, plate can be returned to production position when the other screen needs cleaning

- Since polymer melt flows through second screen while other screen is changed, production does not need to stop

Features

- Works well under high temperatures of 300°C

- Works well at high pressures of 25MPa - 30MPa

- Screen changing area of diameters from 30mm - 250mm

- Provides continuous production

- Precision design provides high pressure performance, large filtration area and good abrasive resistance

- Uses a a precise electrical ruler controller system

- Hydraulic system provides secure operation

- Dual sealing system of a bronze ring and water cooling at the top and bottom of screen changer body

Benefits

- Screen changing is less than 2 seconds

- No air bubbles in product

- Good for thermally sensitive materials

Technical Data

| Model | Screen Area (cm²) | kg/hr | lbs/hr |

|---|---|---|---|

| CSP-70 | 13 | 50 - 150 | 110 - 330 |

| CSP-100 | 30 | 100 - 250 | 220 - 550 |

| CSP-120 | 36 | 150 - 400 | 330 - 880 |

| CSP-150 | 67 | 200 - 600 | 440 - 1,325 |

| CSP-180 | 93 | 300 - 800 | 660 - 1,765 |

| CSP-200 | 110 | 400 - 1,000 | 880 - 2,200 |

| CSP-250 | 160 | 500 - 1,200 | 1,100 - 2,645 |